그래핀 샘플

CVD Graphene on TEM Grid

TEM Grid위에 TCVD Graphene on Cu foil 의 monolayer 그래핀을 transfer 하여 드립니다.

PMMA 0%를 원하시는 분은 따로 메모 남겨주세요!

※대면적 그래핀 구매 가능합니다.

제품 소개

95% 이상의 단일층 그래핀으로 구성되어 있습니다.

저희 그래핀스퀘어는 그래핀 연구와 최신 기술의 응용연구를 하시는

그래핀 연구자를 위해 다양한 연구와 측정 자료를 제공하고 있습니다.

Properties of Graphene

Sheet Resistance : Av.< 250~400 Ω/sq

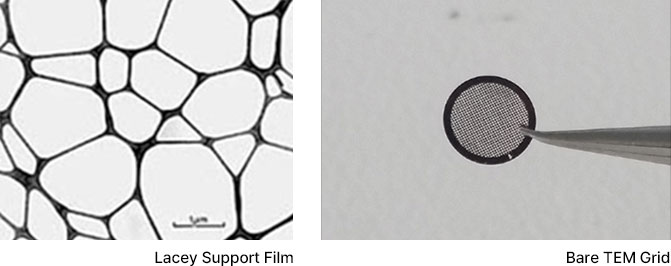

Lacey Carbon Type-A

Mobility : >3500 ㎠/Vs (Max. 17,000 ㎠/Vs

300 mesh

Transmittance : >97%

Copper Frame

Coverage : <30% (PMMA-free), <60% (2-layers)

Specifications

Lacey Carbon Type-A

A Lacey carbon film with a removable Formvar backing on the opposite side of the grid. When the Formvar is removed, by dipping in solvent, the Lacey carbon film remains. These films are stable under all EM(electron microscopy) operating conditions and for use where the presence of Formvar can not be tolerated. Pure Lacey Carbon is more delicate than those with Formvar backing and require more careful handling during specimen preparation. Holes are completely open.

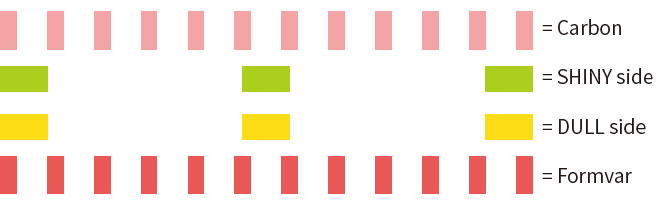

Support Film Product Note, How the Material is Layered on the Grid

Most of the grids used have a distinct “shiny” side and “dull” side when viewed with the naked eye. Generally, the film type as specified in the product name lies on the shiny side of the grid.

Lacey carbon Type A

The Lacey formvar film is applied to the dull side of the grid and carbon depositied onto the shiny side. When the formvar is removed in solvent the carbon film is left on the shiny side.

Grid Cross Section

Substrate Application |

Carbon Type-A |

Is Lacey Film suitable for this application? |

Applications Requiring Pure Formvar |

Not Suitable |

No |

Bacterial Suspensions |

Best |

Yes |

Cell Fragment Suspensions |

Best |

Yes |

Diffraction Studies |

Best |

Yes |

EDS (energy dispersive spectrometry) |

Best |

Yes |

High Resolution Microscopy |

Best |

Yes |

High Temperature Techniques / Heating Stage |

Best |

Yes(Type-A) |

Low Magnification Microscopy |

Good Alternative |

No |

Particulate Suspension, Biological |

Best |

Yes |

Particulate Suspension, Non-Biological |

Best |

Yes |

Powders, Dry |

Good Alternative |

No |

Replicas & Low Temperature Techniques |

Good Alternative |

Yes(Type-A) |

Thin Sections |

Good Alternative |

Yes |

Viral Suspensions | Best | Yes |

Measurement data

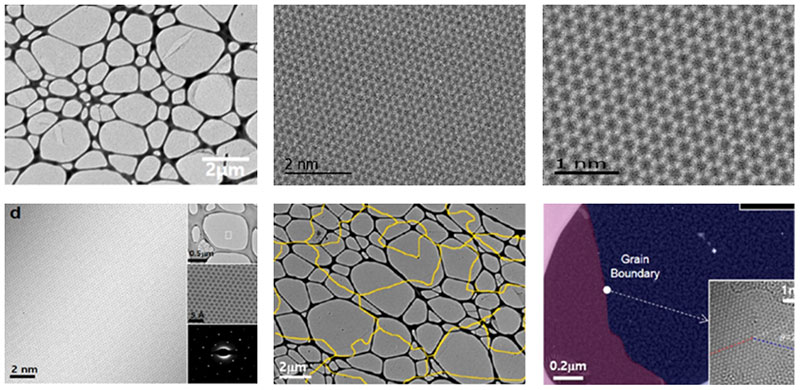

(d) HR-TEM results showing the atomic lattice structures of RT-CVD graphene. The graphene samples were prepared with holey carbon grid (upper inset). The aberration-corrected scanning TEM image provides an atom-by-atom analysis of graphene (mid inset). The diffraction pattern indicates the corresponding graphene is a highly crystalline monolayer (lower inset).

(e) Graphene domain distribution investigated by selected area diffraction patterns (SADP) and TEM imaging. (f) Graphene boundaries of RT-CVD graphene characterized by dark-field TEM and aberration-corrected HR-TEM images . The left and right parts of the grain boundary are imaged with an aperture at the red and blue circled spots of the diffraction pattern (upper inset). The atomic image shows that two graphene domains are smoothly connected with an angle of 36° (lower inset). See also Supporting Figure S2 for more dark-field TEM analyses.

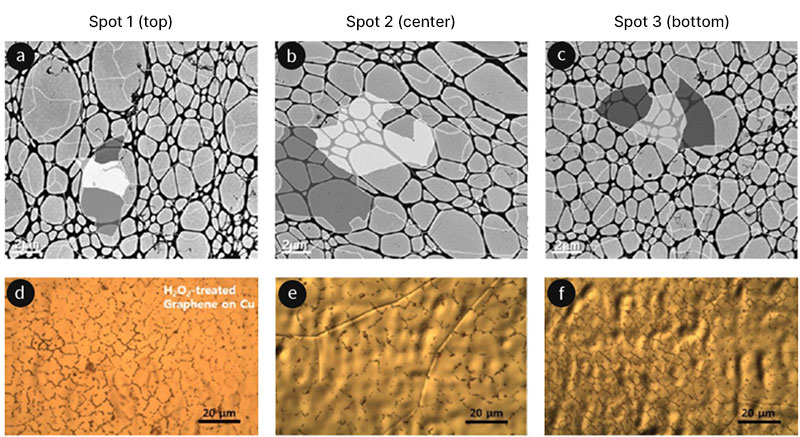

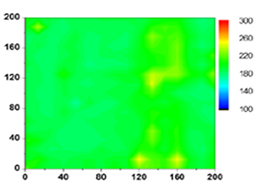

Figure 4. Grain boundary analyses by TEM and OM. (a-c) Grain boundary mapping of RT-CVD graphene films by TEM corresponding to the sheet resistance of spots 1, 2, and 3 in Figure 3a, respectively. (d-f) Grain boundary mapping of H2O2-treated RT-CVD graphene on Cu foils by optical microscopes, corresponding to the red spots 1, 2, and 3 in Figure 3a, respectively. The grain size of graphene in the center region is a few times larger than the edge region. But actually, there is no significant difference in sheet resistance (226, 227, and 230 Ω/sq for spots 1, 2, and 3, respectively).

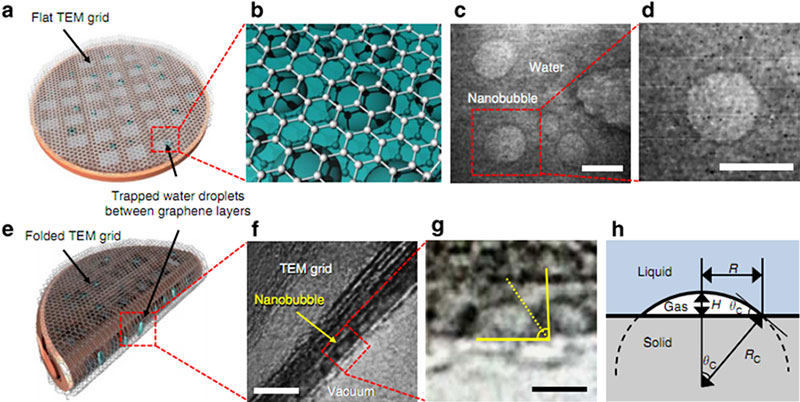

Figure 1 | Morphology of nanobubbles in graphene liquid cell. (a?d) A graphene liquid cell fabricated on a ?at TEM grid (copper or molybdenum) showing the top views of nanobubbles. (c and d) In-situ snapshot images of nanobubbles obtained by ultra-high vacuum (UHV) TEM (200 keV, ~5X10-9 Torr). Scale bars, 10 nm. (e?g) A folded graphene liquid cell showing the side views of nanobubbles. The contact angles were roughly measured to be 6o°?90°. Scale bars for f and g, 10 and 5 nm, respectively.

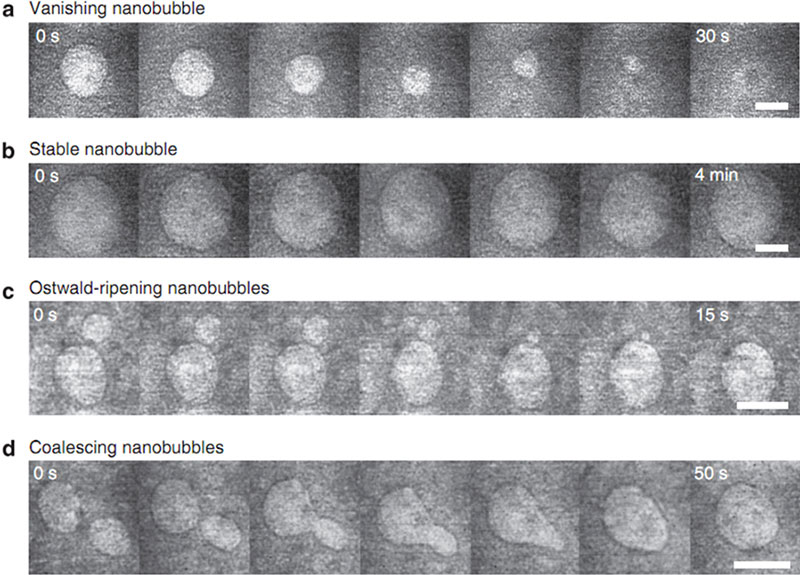

Figure 2 l Time evolution of different kinds of single and double nanobubbles. (a,b) The snap shots of Tem images showing the vanishing and stable nanobubbles, respectively. The nanobubbles smaller than critical radius tend to shrink with time and disappear in ~40s, whereas the larger bubbles persist for more than 10 min. Scale bar, 5 nm. The full movie is available in Supplementary Movie 2. (c,d) The snap shots of TEM images showing the merging of adjacent two nanobubbles observed for 15 and 50 s, respectively. When the nanobubble sizes are significantly different, it show an Ostwald ripening-like merging process, whereas the similar-sized bubbles are coalescing as their inter-bubble boundary breaks. Scale bar, 10nm. The full movie is available in Supplementary Movie 3.

Measurement Data

그래핀스퀘어의 CVD그래핀은 균일하고 뛰어난 품질을 보여줍니다.

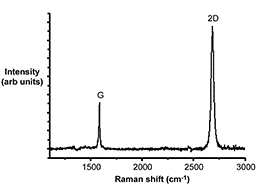

*Raman spectroscope measurement conditions

Laser : 514 nm / Laser Power : 100% / Exposure time : 10s / Accumulation number : 1 /

Hole size : 1 um / Grating : 1200

Raman Spectrum (after transfer)

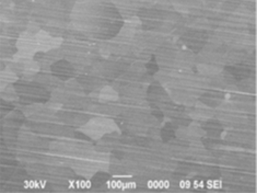

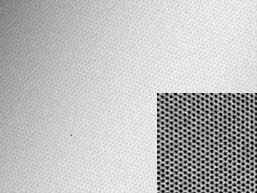

High Revolution SEM Image

Sheet Resistance Uniformity

High Revolution TEM Image

Reference

Park, Jooyeon, et al. “Graphene?Regulated Cardiomyogenic Differentiation Process of Mesenchymal Stem Cells by Enhancing the Expression of Extracellular Matrix Proteins and Cell Signaling Molecules.” Advanced healthcare materials 3.2 (2014): 176-181.

Shin, Dongha, et al. “Growth dynamics and gas transport mechanism of nanobubbles in graphene liquid cells." Nature communications 6 (2015).

Kim, Yeonho, et al. "High-performance ultraviolet photodetectors based on solution-grown ZnS nanobelts sandwiched between graphene layers." Scientific reports 5 (2015).

Sim, Uk, et al. "N-doped graphene quantum sheets on silicon nanowire photocathodes for hydrogen production." Energy & Environmental Science 8.4 (2015): 1329-1338.

Moon, Joonhee, et al. "One?Step Synthesis of N?doped Graphene Quantum Sheets from Monolayer Graphene by Nitrogen Plasma." Advanced Materials 26.21 (2014): 3501-3505.

Kim, Sang Jin, et al. "Simultaneous etching and doping by Cu-stabilizing agent for high-performance graphene-based transparent electrodes." Chemistry of Materials 26.7 (2014): 2332-2336.

Kim, Jung Kyu, et al. "Surface-Engineered Graphene Quantum Dots Incorporated into Polymer Layers for High Performance Organic Photovoltaics." Scientific reports 5 (2015).

보관 방법

Oxygen에 의한 영향을 줄이기 위해서 발송되는 진공포장 상태를 유지하거나,

개봉 후에는 진공 데시케이터에서 보관하십시오.

그래핀스퀘어의 특장점

세계최초! 대면적 그래핀을 합성한 그래핀 스퀘어

Nature Nanotechnology 2010 cover image.

다년간의 Transfer 노하우

최적화된 연구 환경에서 진행됩니다. Less residue, clear surface, Coverage 95% 이상,

기판 표면 개질 등

그래핀 손상을 최소화하는 Package

질소 충진 진공포장 표면 contact zero Handling이 용이한 packing

Optimized Graphene

옵션/추가공정으로 연구방향에 맞는 그래핀 샘플 advice 그래핀 연구 경험이 없으신 분들, 새로운 기판에 그래핀 적용을 원하시는 분들께 추천합니다.

확실한 Warranty Service

품질 이상 시, 100% 재제작 언제든 연락주세요.

CVD 합성 그래핀부터 장비 판매까지

All about Graphene

장비부터 Transfer까지 모든 공정에 대한 이해를 기반으로 오직 그래핀만을 위한 CVD 장비 취급부터 그래핀만을 위한 합성, 전사, 포장 공정.

배송

포장 과정

01

질소 충전, 진공 포장

02

완충재 포장

03

택배사 픽업

| 주문 과정 |

고객 주문/결제 |

그래핀 샘플 제작 |

포장 |

배송(우체국 택배 이용) |

|---|---|---|---|---|

| 진행 현황 |

고객의 주문을

확인하고 검토합니다 |

고품질 샘플을 제작하고

품질검사를 진행합니다 |

운반과 취급에 대비해

안전하게 포장합니다 |

주문하신 제품을 발송합니다

(일반적으로 3영업일이 소요됩니다) |