CVD Equipment

TCVD-RF100CA

Thermal Chemical Vapor Deposition

The main Thermal CVD technology involves adding gases to the pressurized reactor at high temperature of about 1,000℃ where thin film is synthesized onto substrates.

Size

Features

Up to 10 gases 3 MO sources for gas-phase synthesis.

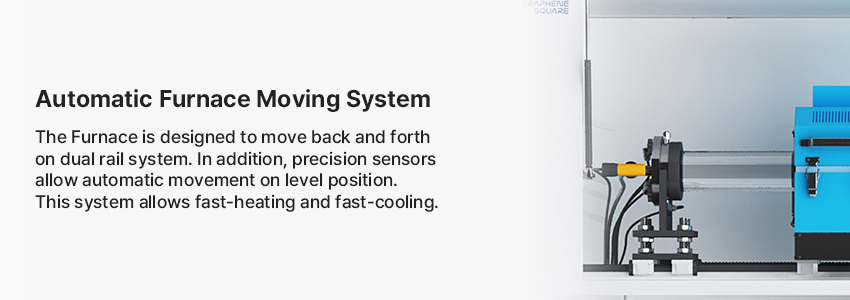

Motor-controlled movable heater for fast heating cooling (patented).

Fully computer-controlled programmable recipes.

TCVD100 platform : Proven performance for ~100 systems for more than 5 years.

Invited training for full sample preparation processes.

*Price will be determined after consultation. (Different customization from the standard parts will affect the overall price.)

Advantage

Specifications

Both End chamber(Stainess) - All parts cooling by water

Quartz Main chamber

Gas control unit ( Mass flow controller) - 3channel standard

340liter/min Oil rotary pump

Pneumatic On/off valve with Auto pressure control Throttle valve

Programmable Temperature controller

High Temperature Furnace(Max1200℃)

Rapid Cooling system by furnace moving

Atmospheric and Vacuum Processing

Anti-contamination system by inner tube

Vacuum gauge unit(Capacitance/Convectron)

1 year warranty

On-site install and training

System Program ( Auto processing system)

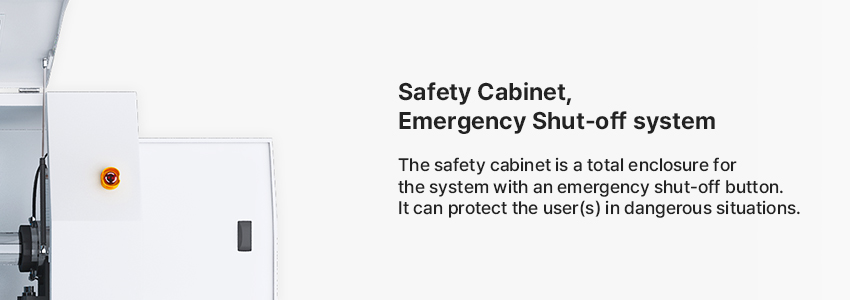

Safety Cover ( Connected exhaust system )

High Vacuum processing (Pump/Gauge/valve unit)

RF plasma ( ICP type )

Options

Rapid thermal processing furnace by IR lamp source

MF power induction heating process Max temp 1600℃

MFC(Mass flow controller) addtion total 12channel

Dry vacuum pump ( Scroll / booster / industry)

Safety interlock system(Water / Air/gas leak)

Tungsten filament gas source cracking

Additional Furnace for source evaporation

High Vacuum processing option (Pump/Gauge/valve unit)

Source delivery system ( Bubbler / Gas / Solid )

System Utility ( Chiller / scrubber / gas cabinet )

Consumable Parts

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

Facility Requirements

Electrical power |

220VAC 1ph 40A |

Compressed air |

0.5~0.6Mpa |

Compressed air input size |

6 mm one touch fitting |

Cooling water in/out |

3/8" lok fitting |

cooling water flow |

Air temp 5~7liter/min |

cooling water pressure |

0.1~0.2Mpa |

Safety exhaust size |

6 mm one touch tube |

Gas input pressure |

40psi |

Gas port |

10ch standard (Option 2ch Expansion) |

Gas port Size |

1/4"lok fitting |

Pump exhaust |

NW25 |

Rotary pump capacity |

340liter/min |

Vent |

1/4"lok fitting |

Dry pump exhaust |

NW16 |

Dry pump capacity |

250liter/min |

Cold trap LN2 port |

NW16 |

Customer List

| ETH IBM Lab | Seoul National University |

| Israel |

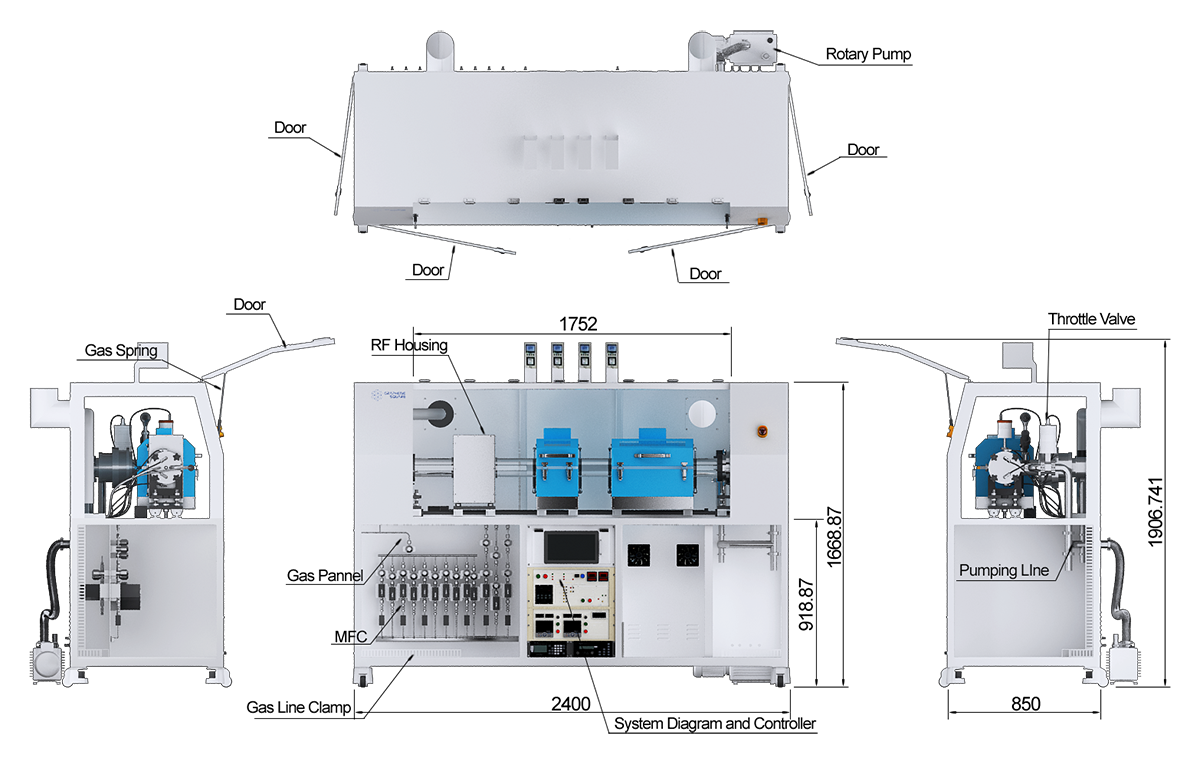

Layout

Quality Assurance

If you find a part abnormality or system error in your equipment within the period, please contact us immediately and a repairman will be dispatched immediately within 24 hours.

Delivery period

Equipment Purchase Process

01

Quotation Request (info@graphenesq.com)

Quotation Request and Quotation provided

02

Confirmation of intention to purchase

Customer's intention to purchase

(Purchase Order from Customer)

03

Invoice / Payment

Provide Invoice and Payment data

04

Provide Production • Training program

Provide machine production and training program upon completion of the first deposit

05

Equipment Operation Test /

Product packaging, Shipment

After production is completed, product packaging and shipping are carried out

06

Arrival is completed

Arrival is completed at the customer site

within up to 4 days