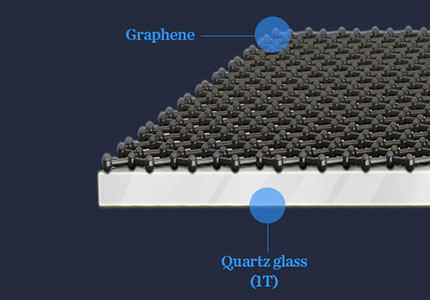

Graphene Samples

CVD Graphene on Glass

※Large-Area Graphene Available for Purchase

Product and Service Overview

Size

10 mm X 10 mm, 10ea

10 mm X 10 mm, 20ea

50 mm X 50 mm, 1ea

2″ x 2″, 1ea

3″ x 3″, 1ea

80 mm X 80 mm, 1ea

Properties of Graphene

Film morphology : Continuous Monolayer(>95%)

Sheet Resistance : Av. < 250~400 Ω/sq (after transfer)

Mobility : >3500 ㎠/Vs (Max. 17.000 ㎠/Vs)

Transmittance : >97%

Subtrate : Quartz plate (1T) (Standard)

Domain Size:~10 ㎛

Specifications

Flame fused ingots are re-heated to make many shaped plates. This plates can be used for window material, mask substrate and flanges.

Another hand the ingot is drawn to rod for quartz boat, fabrication welding rod and optical fiber parts. OH contents will be 120~260 ppm as general

Chemical element composition (Typical data)

| Al | Fe | K | Li | Cu | NaS | B | Ca | Mg | P | Ti | OH |

| 20.00 | 0.40 | 1.00 | 1.4 | 0.01 | 1.50 | 0.20 | 0.50 | - | - | - | - |

Transparent Quartz Glass Property

| Density | 2.21 × 10³ kg/m³ |

| Hardness | 580 KHN100 |

| Tensile Strength | 4.9 × 10⁷ Pa (N/m²) |

| Compression Strength | > 1.1 × 10⁹ Pa |

| Coefficient of Thermal Expansion (20–300℃) | 5.5 × 10⁻⁷ cm/cm·℃ |

| Thermal Conductivity (20℃) | 1.4 W/m·℃ |

| SpecificHeat (20℃) | 680 J/kg·℃ |

| Softening Point | 1700℃ |

| Annealing Point | 1210℃ |

Optical property

Our transparent quartz material has excellent transmission, especially ultra-red zone and visible area compare with ordinary glass.

Transmission of UV is related with metal impurities. 2730nm wave indicate OH content absorption and volume.

Applications

Energy electrode (solar cells, secondary batteries, fuel cells, supercapacitors)

Functional composite materials (ultra-light strong composite for cars & aerospace)

Heat dissipation (LED lighting & ECU units)

Barrier (gas barriers, electromagnetic wave barriers)

Biomedical applications (substrate for stem cell therapy, graphene liquid cells for electron microscopy)

Main Target

For those researchers in need of graphene transfer onto transparent and flexible circuit board

For those researchers in need of high quality Graphene on Quartz glass

Additional Options

Reduce sheet resistance by Multi-layers graphene (Graphene stacking, laminated). (ex. 2, 3, 4, …, 10-layers)

Various sizes.

Transfer graphene onto Electrode patterned boards.

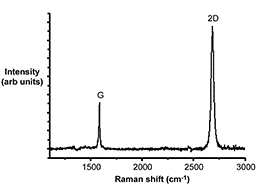

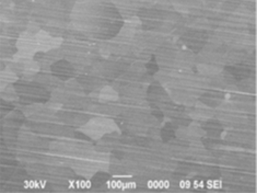

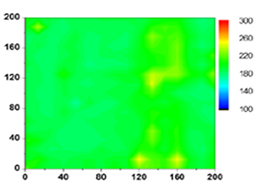

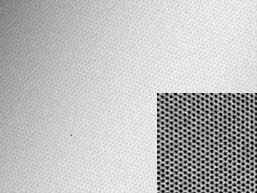

Measurement Data

Graphene Square’s CVD graphene demonstrates uniformity and outstanding quality.

*Raman spectroscope measurement conditions

Laser : 514 nm / Laser Power : 100% / Exposure time : 10s / Accumulation number : 1 /

Hole size : 1 um / Grating : 1200

Raman Spectrum (after transfer)

High Revolution SEM Image

Sheet Resistance Uniformity

High Revolution TEM Image

Reference

Y. Lee et al. Wafer-Scale Synthesis and Transfer of Graphene Films. Nano Lett. 10, 490-493 (2010).

S. J. Kim*, T. Choi* et al. "Ultra-Clean Patterned Transfer of Single-Layer Graphene by Recyclable Pressure Sensitive Adhesive Films" Nano Letters 15, 3236?3240 (2015).

Package

We have taken special care and use vacuum packaging to minimize damage on the research surface of graphene. Our graphene film sample packaging is unique such that the graphene surface does not come in contact with the inner package surface. As a result, our graphene samples are not damaged nor scratched during the shipping process. We suggest use of tweezers to handle graphene.

Storage Instructions

To minimize the effects of oxygen, keep the graphene in its vacuum-sealed packaging during shipment, or store it in a vacuum desiccator after opening.

Customer List

| National University of Singapore | Sabanci University |

| Nokia Research Center | Korea Basic Science Institute |

| HRL Laboratories | Seoul National University |

| LG Display | SungKyunKwan University |

| Korea Advanced Institute of Science and Technology | University of Bari Aldo Moro |

| Korea Atomic Energy Research Institute | Agency for Defense Development |

Graphene Square Advantages

World’s first large scale graphene synthesis towards commercialization.

Nature Nanotechnology 2010 cover image.

Many years of know-how in transfer method.

Coverage at above 95%, low residue. Most optimized R&D environment.

Our sample package is designed to minimize graphene damage.

Vacuum packaged, nitrogen filled. Easy to handle.

Optimized Graphene

We give advice and make suggestions to the beginners in graphene research. Offer Graphene on various and unique substrates.

Our commitment

We promise to deliver a level of quality unmatched and to our customers’ satisfaction.

All about Graphene-from thermal CVD equipment to graphene synthesis and transfer process with know-how.

Understanding of the whole process from the graphene synthesis, transfer, proper packaging with sound research is our key to success.

Delivery

Packaging Process

01

Vacuum packaging, nitrogen filled

02

Air cushion packaging

03

Ready for pick up by courier service

| Order process |

Customer order and |

Produce graphene |

Packaging |

Delivery |

|---|---|---|---|---|

| Status |

Review and confirm

customer order |

Produce and inspect for

high quality product |

Expert and protective

packaging for S&H |

Estimated time of delivery is three business days

(Detailed shipment tracking on fedex.com) |